Distributed Brands

View Catalogue

JRC Spare Parts

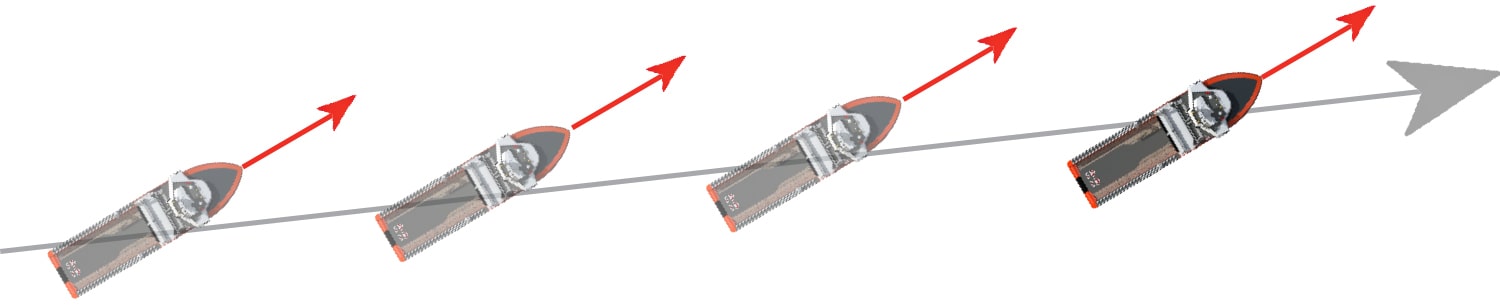

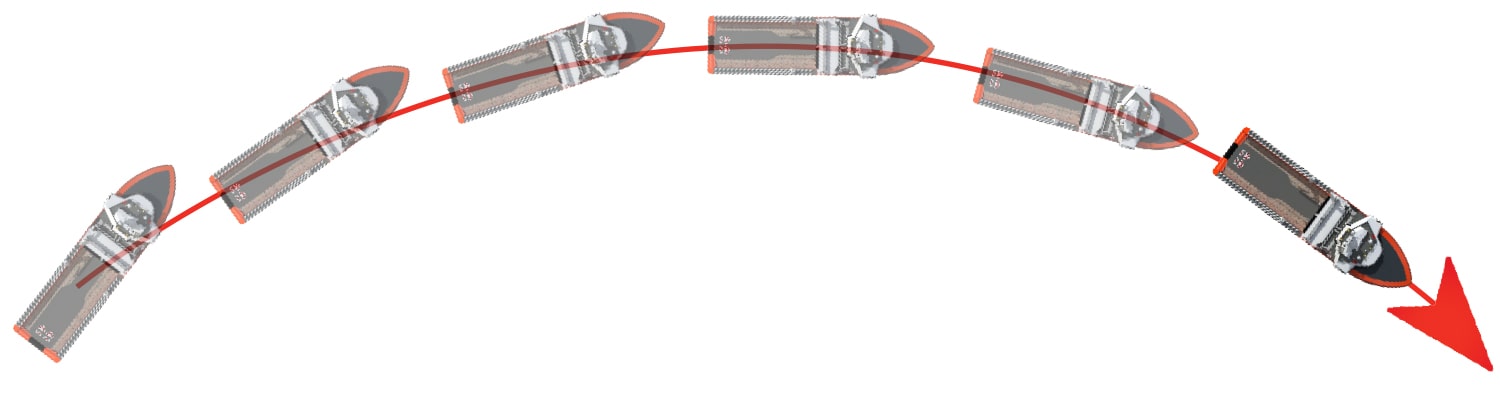

Specialising in the design and manufacture of products for commercial workboats and fishing vessels.

For over 30 years Glomex has produced the most complete range of marine antennas, recognized as the best choice by the most important boat builders and by millions of boat owners.

With over 30 years in the water filtration industry, Parker Village Marine is the world’s leader in reverse osmosis watermakers.

HRO Systems was founded in 1975 and was a pioneer in creating the first line of small scale reverse osmosis desalination systems.